Freeze Drying

-

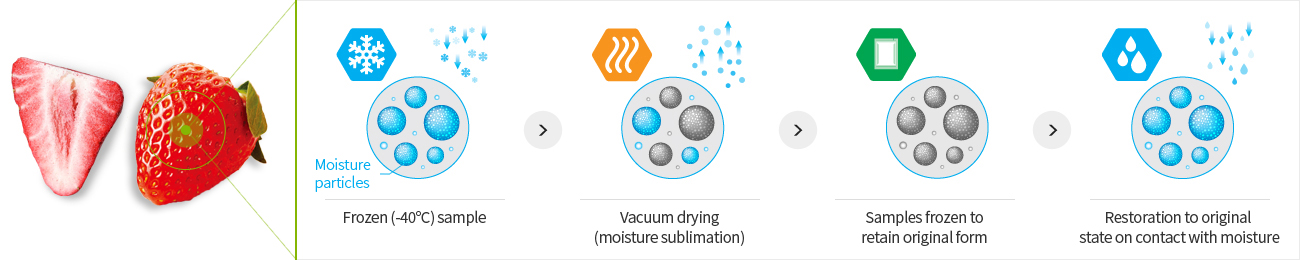

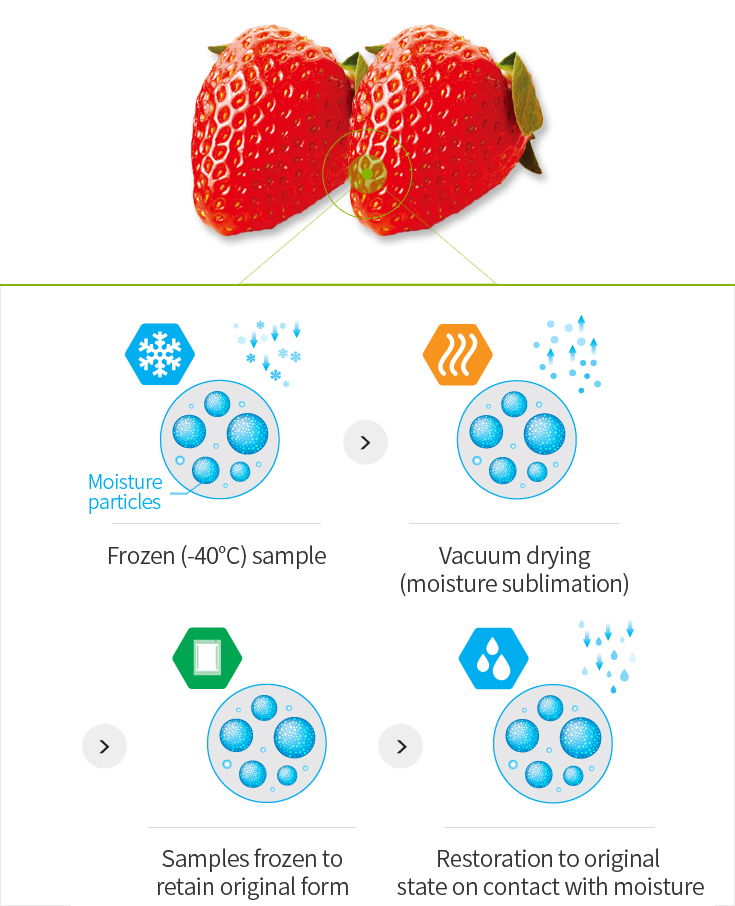

01Quick freezing

Flash freezing to minimize loss of cells and nutrients

-

02Vacuum freezing drying

Drying of products by sublimation of ice in vacuum. Sublimation refers to conversion of ice into gas without passing liquid state (water). In order to dry products while maintaining their frozen state, we process the products with low heat in a vacuum to facilitate sublimation. Sublimation only occurs when the temperature on the surface of the ice and the steam pressure are lower than the triple point. The supercooling point undergoes sublimation in a drying room where a certain level of vacuum (1-0.1 Torr) is kept to dry the products.

It refers to flash freezing of raw materials to freeze the moisture then lowering the pressure to dry the products while

maintaining their frozen state.

The products are heated at a low temperature with a low vacuum state,

enabling moisture to be removed from the products by sublimating the ice.

This minimizes the loss of the product's form, color, flavor, and nutrition, and can

be described as

the best way of removing moisture from products by drying.

This process does not destroy the tissue and allows the products to be stored for a long time. The material quickly returns to its original state by adding water or solution.

- By drying products at a low temperature, only small thermal degeneration is caused, minimizing the loss of fragrance.

- This method allows a raw material to be stored for a long time while minimizing its loss of substances.

- It enables prolonged storage of products at room temperature while minimizing property changes of the material being dried.

- Since this method dries products in the frozen state, the products do not experience thermal degeneration, meaning they undergo minimal physical, chemical, and enzymatic reactions.

- Materials can be preserved with minimal loss of shape, size, flavor, fragrance, and nutrition.

- The porous structure provides excellent water stability.

- Deactivating a material allows it to keep its form and substance, making it easier to store the material.

- It is extremely low in moisture content, and light in weight, allowing a material to be preserved for a long time without additives.